Platen

Hot Foil

Printing Machines

Toner Hot

Foil Printing

Machine

Suppliers to

Her Majesty's Government,

Schools, Colleges,

Universities, Industry

and new Business Start Ups.

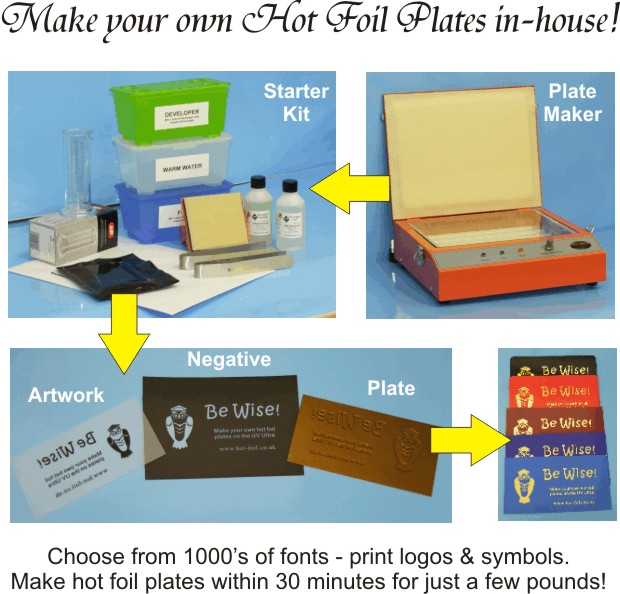

(Plate making accessories available at extra cost - please see below)

This Mini Starter Kit costs £64.00+VAT

We

supply a mini optional 'Starter Kit' for making polymer hot foil plates. The

Starter Kit consists of:-

2 x A4 Artwork Sheets (For laser printers)*

2 x A4 Negative Film

100ml Negative Developer

100ml Negative Fixer

Washout Pad

Measuring Cylinder

2 x Lifting Tongs

10 x Polymer Hot Foil Plates cut to Business Card Size (Metal backed for

better heat transfer)**

3 x Tubs for Developer, Water and Fixer

Instructions

Images shown above are for illustration purposes only.

* We do not recommend the use of inkjet paper

for creating artwork as inkjet printers do not always produce dense enough

images which are so vital for the correct production of hot foil plates.

** We only recommend the use of metal backed

polymer plates for hot foil printing as they transfer heat far better than

plates which do not have metal backing.

On-going supplies/costs

20 x A4 Artwork Sheets £12.00+VAT

1 Liter of Developer £11.60+VAT

1 Liter of Fixer £11.60+VAT

20 x A4 Negative Film £27.00+VAT

1 x A4 Sheet of Polymer Hot Foil Plate (uncut) £21.00+VAT

(or cut into 10 x equal Business Card Sizes £22.50+VAT

With improvements in the quality of polymers,

better quality exposure unit, and better grades of foils, it has now

become possible to create your own hot foil polymer plates in-house, at a

fraction of the cost of metal plates.

With metal Type almost extinct and costing hundreds of pounds per font,

you can now make your own hot foil using any

font on your PC together with logos and symbols. No need to keep

investing money in expensive Type when you now have the luxury of making

your hot foil plates in-house. A single font can cost you about the

same price as our Plate Maker - with our Plate Maker, you can print in

1000's of different fonts without having to outlay 1000's of pounds in

Type!

No more waiting for days for your plate to arrive by post - now you can

take an order and deliver the product within the hour!

The Hot Foil Plate Making Process (simplified)

-

Create mono artwork onto transparency artwork paper (using laser printer is best)

-

Place artwork and Negative Film together in the 'UV Ultra' plate maker and expose for a few seconds

-

Wash Negative in Fixer solution and then develop in developer solution

-

Once dry, place negative film and blank polymer plate into the 'UV Ultra' plate maker and expose for

a specified time period. -

Wash plate in hot water, which creates a relief image of your text and logos

Dry plate, post expose in UV

Ultra Unit - Your hot foil plate is now ready to use.

~ Total time taken to make a hot foil plate from scratch is about 30

minutes.

~ Several plates can also be made at once on our UV Ultra Unit.

~ Cost to produce a business cards size plate is around £2.00 each.

Benefits of making your own Hot Foil Polymer Plates

-

Keeps set up costs low (Thus making you more competitive)

-

You can turn jobs around faster (e.g. same day)

-

No need to keep or invest in metal type - use any font on your PC

-

Incorporate logos etc. without any problem

-

Ideal for one-off jobs or where small runs are required where the cost of a

metal plate cannot be justified.

Metal/Plate Cutting

Shears

Two powerful, cost effective, shears which

have the ability to accurately cut PCB laminates, plastics, polymer plates

up to 2.00mm thick and aluminium up to 1.5mm. Now you can cut polymer

plates

to size, on demand.

An important feature of these shears is

safety. Free access to the cutting area is prevented by heavy Perspex

shielding extending along both sides of the blade. A safety latch is

fitted to the pivot to prevent operation without it first being released.

For positional accuracy the cutting bed is fitted with a rule which is

recessed to assist in securing the PCB or sheeting whilst cutting is in

progress.

The 8" Cutter is extremely compact with an overall height of

only 575mm and a footprint of 335 X 140mm. It has a cutting bed of 110mm

wide from the blade although wider material can be cut.

The larger 12" Cutter will cut materials up to has a

height of 670mm and a footprint of 440 x 245mm. It has a larger cutting

bed 225mm wide from the blade although once again wider material can be

cut.

You can also cut metal plates with a tin cutter (like a scissors) from DIY

stores, but in our opinion, they can leave

a kink in the plate as you cut through the plate in stages. This can

adversely affect the quality of the printing plate.

What is required to ensure

good quality polymer plates?

Factors such as quality of artwork, correct exposure times, washing

out, use of correct grade of foil (for hot foil), selecting the

correct hot foil machine temperature, dwell time, substrates etc. can all affect

the quality of your finished plate and hence printing quality. We will

give you good guidelines with your purchase (and also offer after-sales

telephone support) but would like to stress that some, or a

combination of such factors can affect the quality of your plate and

printing which are out of our control for which we cannot hold any

responsibility. Our

exposure units are sold on this strict understanding.

It must however be pointed out from the outset (which others fail to mention) that polymer plates will not totally replace the need for metal plates. Unlike polymer plates, metal plates is not something which you can make at home due to their complexity. Making Polymer Plates requires practice and following tips contained within our instruction manual closely.

Metal

plates may still be required where you have the following within

your design: very fine fonts, fine lines, large print areas etc. Metal

plates may also be required for certain surfaces.

These plates work best on machines which have 'toggle action' and those

with pressure adjustment screws.

Copyright 2006 Creative Printers of London www.hot-foil.co.uk